- Toolbox

-

Create New Topic

Create New Topic

-

Index

Index

-

Search

Search

-

Changes

Changes

-

Notifications

Notifications

-

RSS Feed

RSS Feed

-

Statistics

Statistics

-

Preferences

Preferences

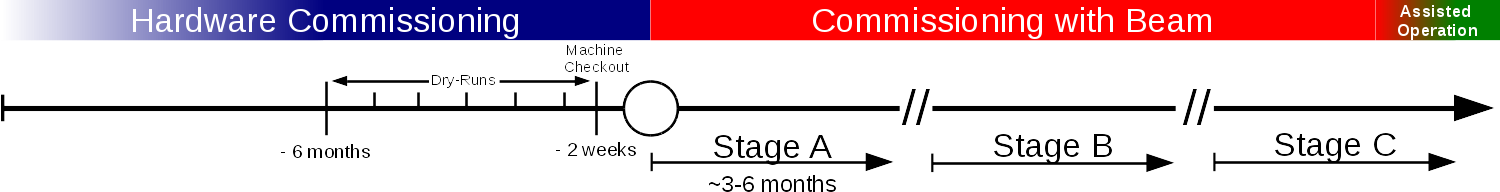

The Commissioning with Beam (BC) for FAIR is grouped into the following three stages:

The Commissioning with Beam (BC) for FAIR is grouped into the following three stages:

Stage A - Pilot Beams

- main aim:

- drive the beam expeditiously through the BeamProductionChain (BPC): from the sources, through the synchrotrons, beam transfers, up to the experimental targets/storage rings

- check basic 'accelerator mechanics': threading, injection, capture, cool, convert, acceleration/decelerate, stripping & extraction

- identify beam-related limitations: polarities, RF, beam instrumentation, machine alignment, effective physical machine aperture, …

- always done with 'safe' resp. low-intensity/brightness beam

- initially with 'easily available' ions (e.g. U28+, Ar → simpler optics, beam dynamics, etc.), then protons (tests transition crossing, etc.)

Stage B - Intensity Ramp-up & Special Systems

- main aim:

- achieving and maintaining nominal machine performance for a limited number of reference beam

- check that the accelerator design and systems can achieve (near) nominal beam parameters, e.g. beam intensities, nominal transmission and beam losses for e.g. U28+ & proton beams, etc.

- commissioning of e.g. e-cooler (if not needed earlier), slow extraction, transverse fast feedbacks

- commissioning and validation of machine protection & interlock systems

- possibly unsafe operations always preceded by checks with safe beam

Stage C - Production Operation with nominal Intensities

- main aim:

- make fast setup and switch-over between different BeamProductionChains routine

- push physics and beam parameter performance (intensity, brightness/emittance, momentum spread, …)

- identify and improve upon bottlenecks impacting FAIR's 'figure-of-merit

- improve the machine model using beam-based techniques

- N.B. first time counted as 'commissioning' or 'assisted operation' → later: 'regular operation'

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors.

Ideas, requests, problems regarding Foswiki Send feedback | Imprint | Privacy Policy (in German)

Ideas, requests, problems regarding Foswiki Send feedback | Imprint | Privacy Policy (in German)

This website is using cookies. More info.

That's Fine